About Us

Trinity Tooling and Machinery (Europe) Ltd is a supplier of wide range of plastic extrusion tooling & machinery worldwide.

Trinity Technology is world wide leader in Extrusion tooling. We now also supply Injection mold to various industries.

Trinity has exported tooling and machinery to the countries like United States, Turkey, Russia, Canada, Korea, Japan, Thailand, India, Iran and several European countries.

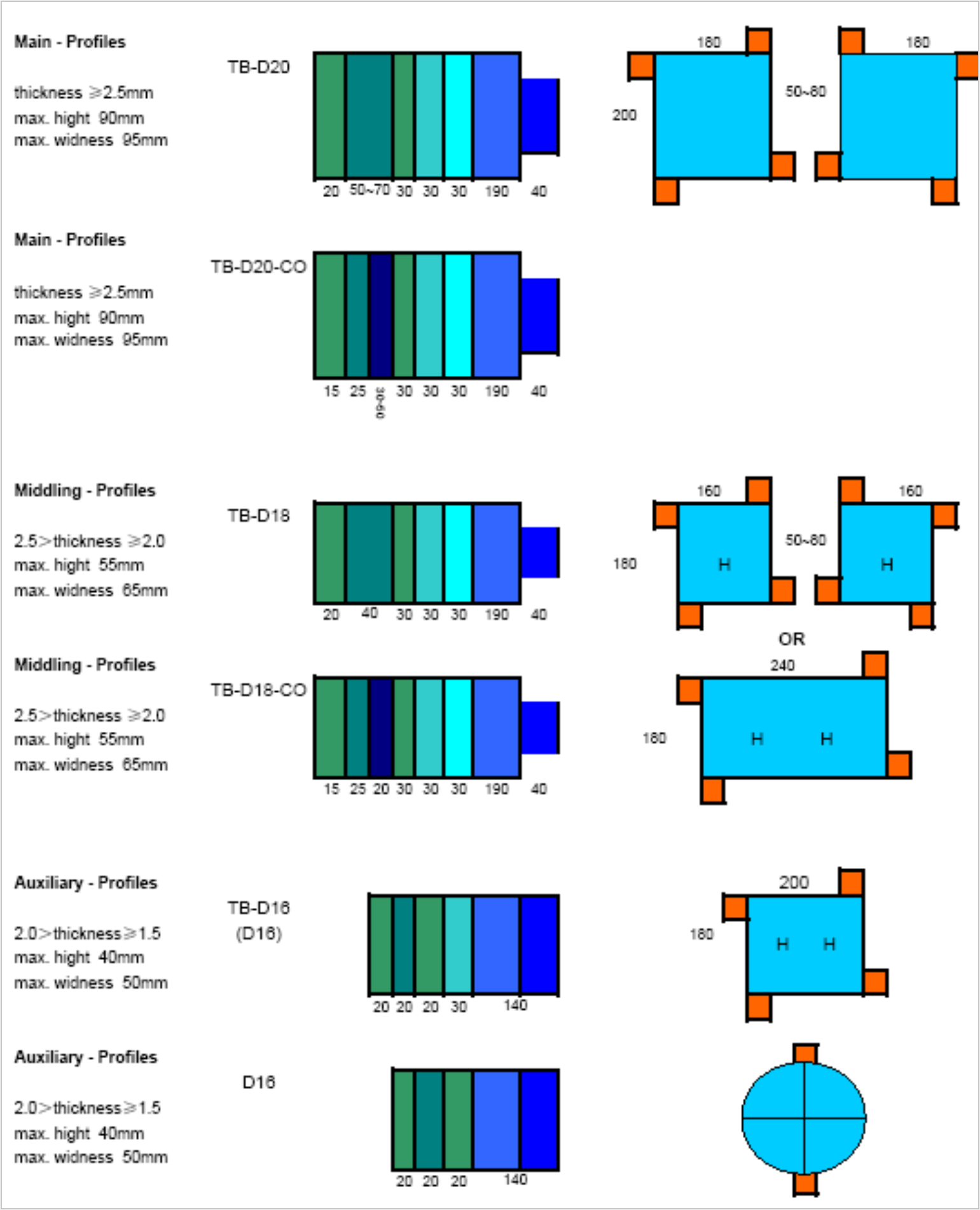

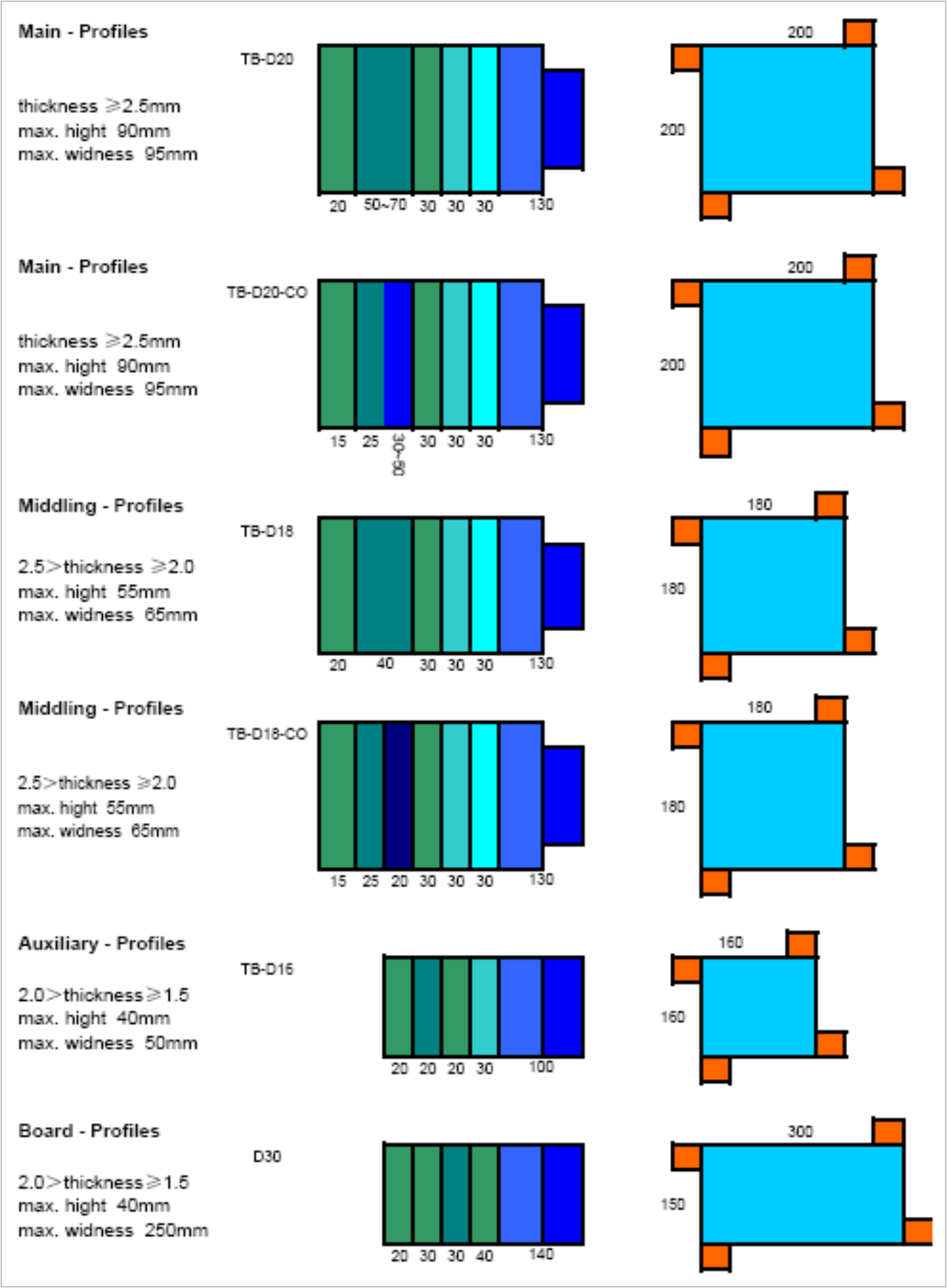

Profile Range

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

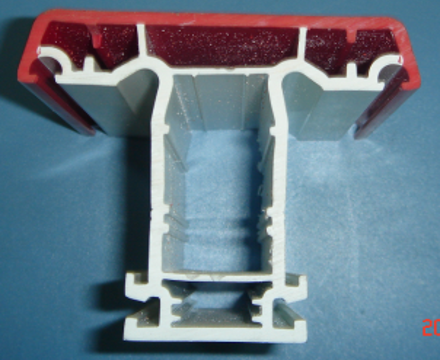

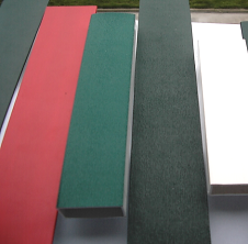

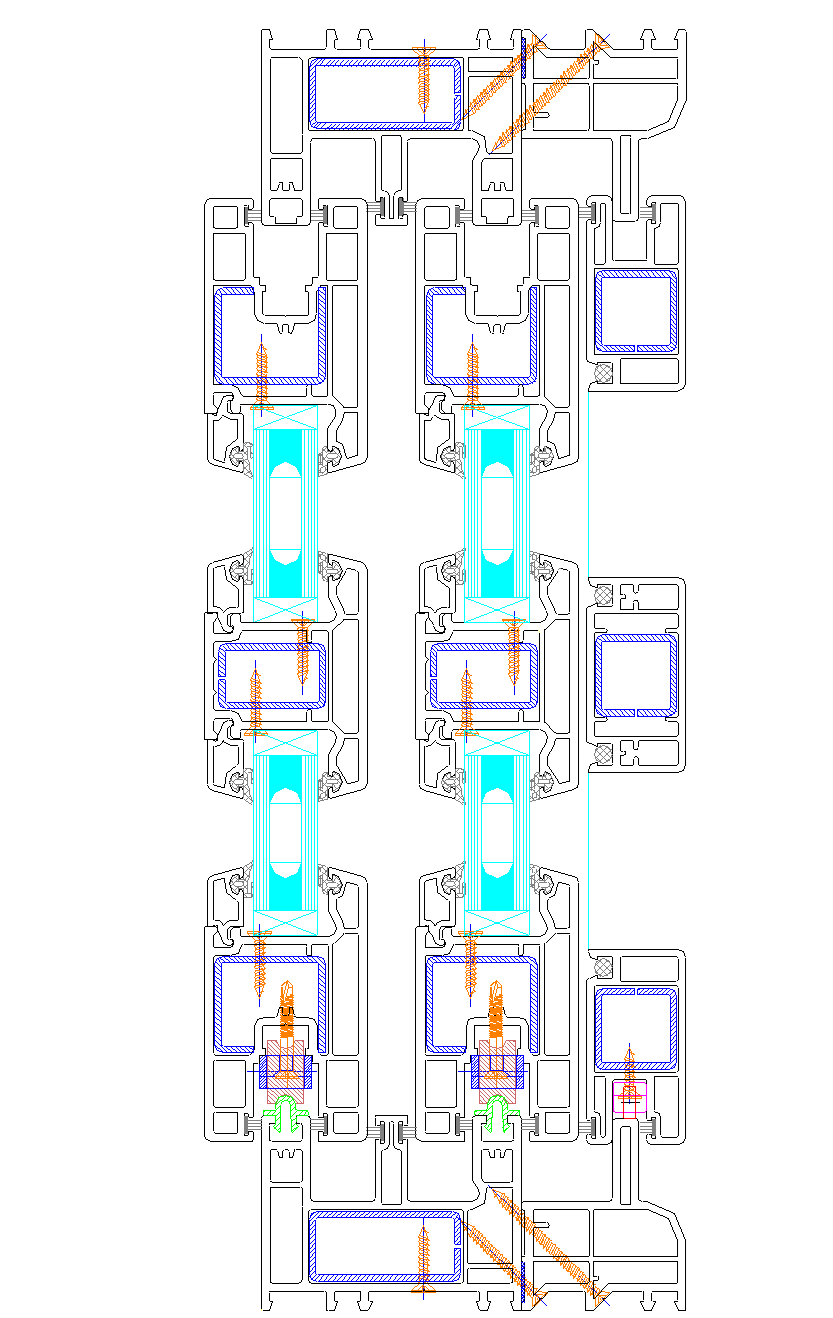

Extrusion Tooling Range

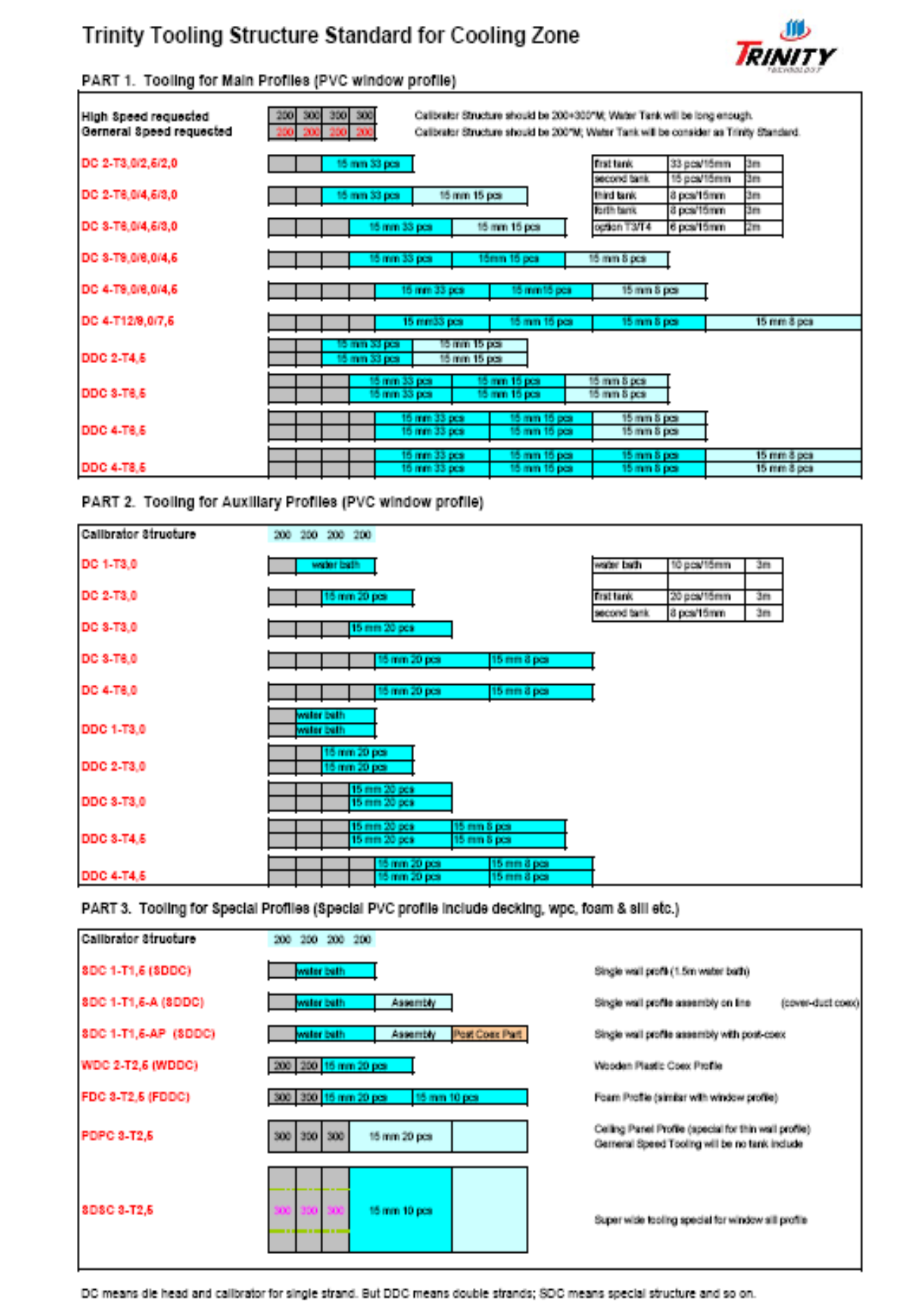

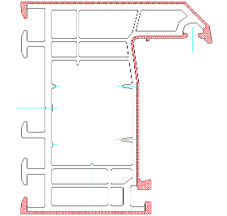

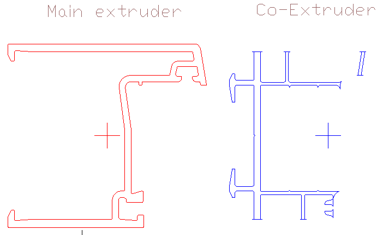

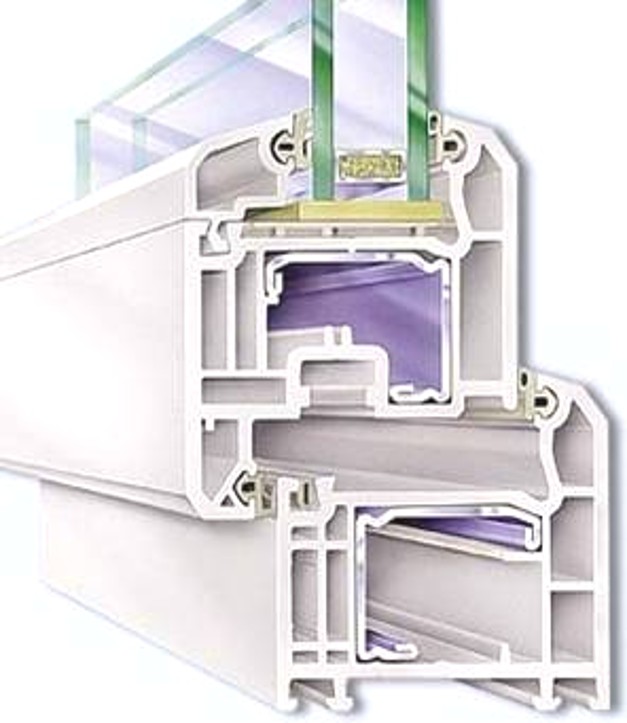

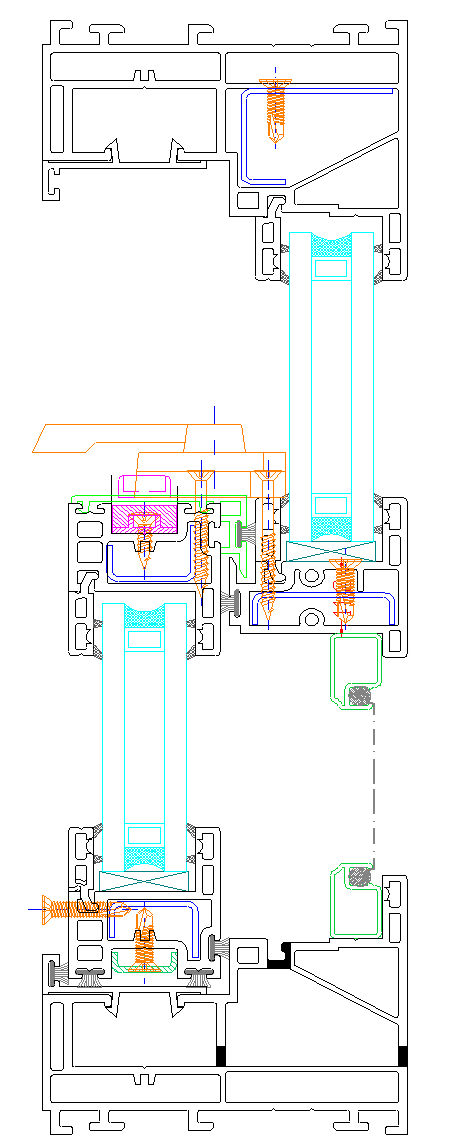

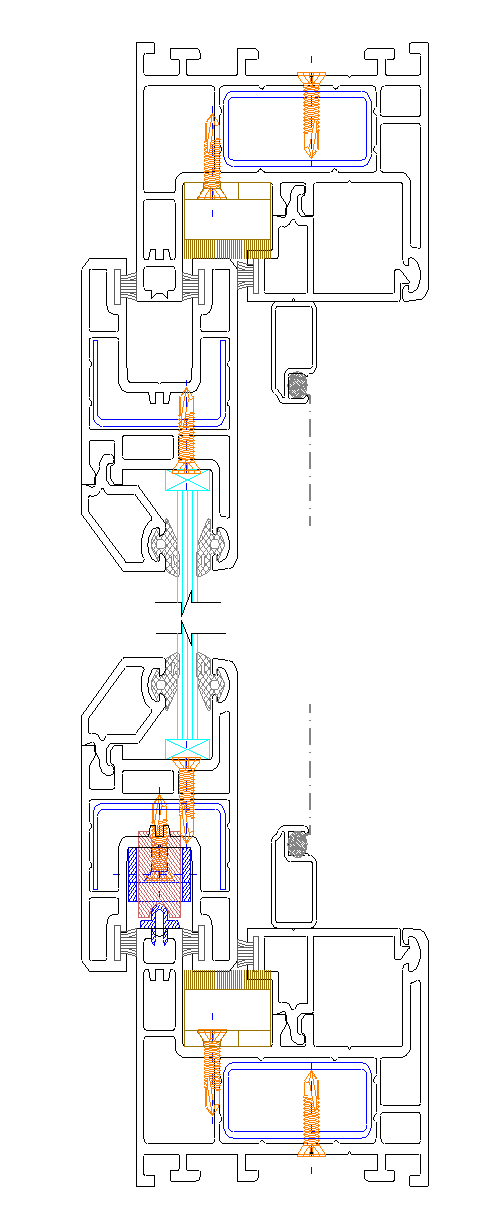

- Extrusion tooling for rigid PVC window & door profiles

- Extrusion tooling for Sheet extrusion

- Extrusion tooling for window Cill

- Extrusion tooling for ceiling panel and decoration panel

- Extrusion tooling for cable channel profile

- Extrusion tooling for Multi-Strands and high speed profile

- Extrusion tooling for PVC Foam profile

- Co-extrusion tooling for wooden-plastic(WPC) profile

- Co-extrusion tooling for Multi-colour window profile

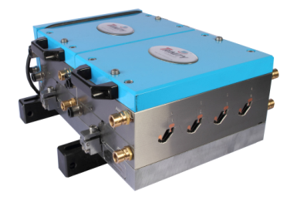

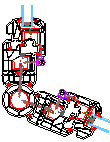

Cyclone Water Tank

Water Tank with Trinity patent is designed professionally, its special cyclone water flow guarantees perfect cooling for high speed profile production.

The Water Tank is made by Fiber Glass, which gives extrusion tooling a comparative long life with good abrasion resistance.

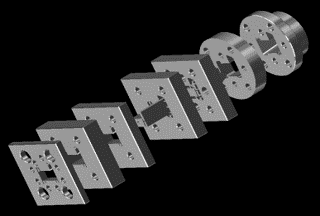

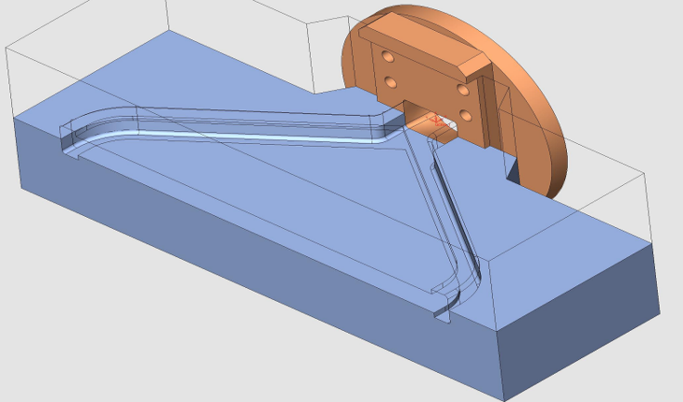

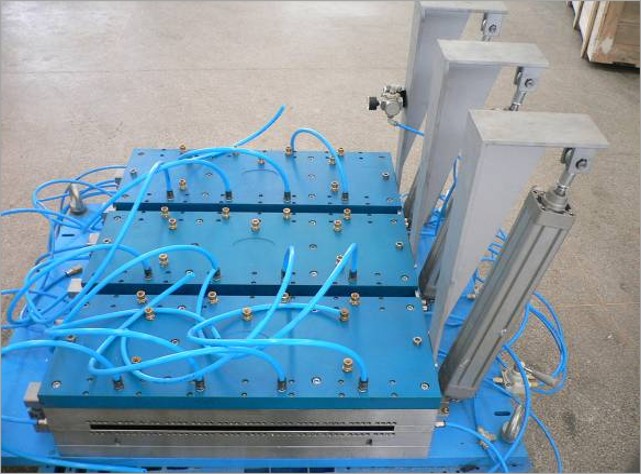

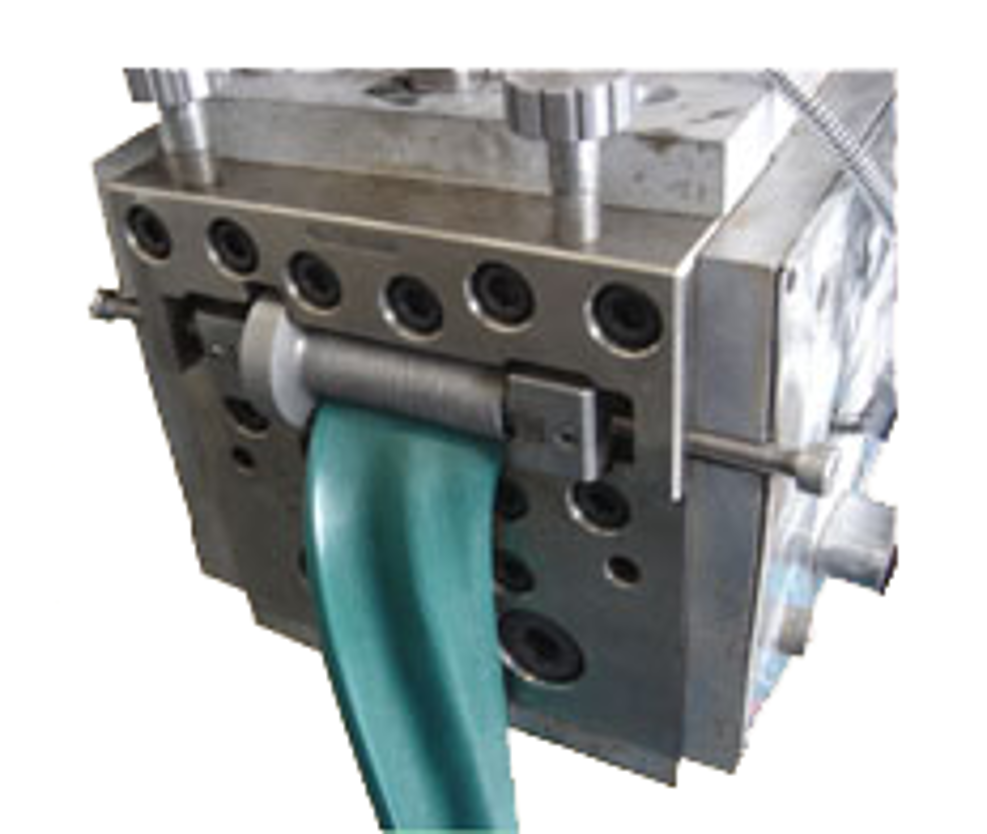

Assembly of Multi-Strand Tooling

Trinity patent technique on extrusion of cable channel & cover’s assembly on line.

Up to 4 strand extrusion for different profiles at one time

Up to 4 strand extrusion for different profiles which have assembly relations

Up to 4 strand extrusion for soft PVC co-extrusion profiles with assembly on line

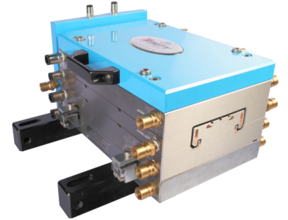

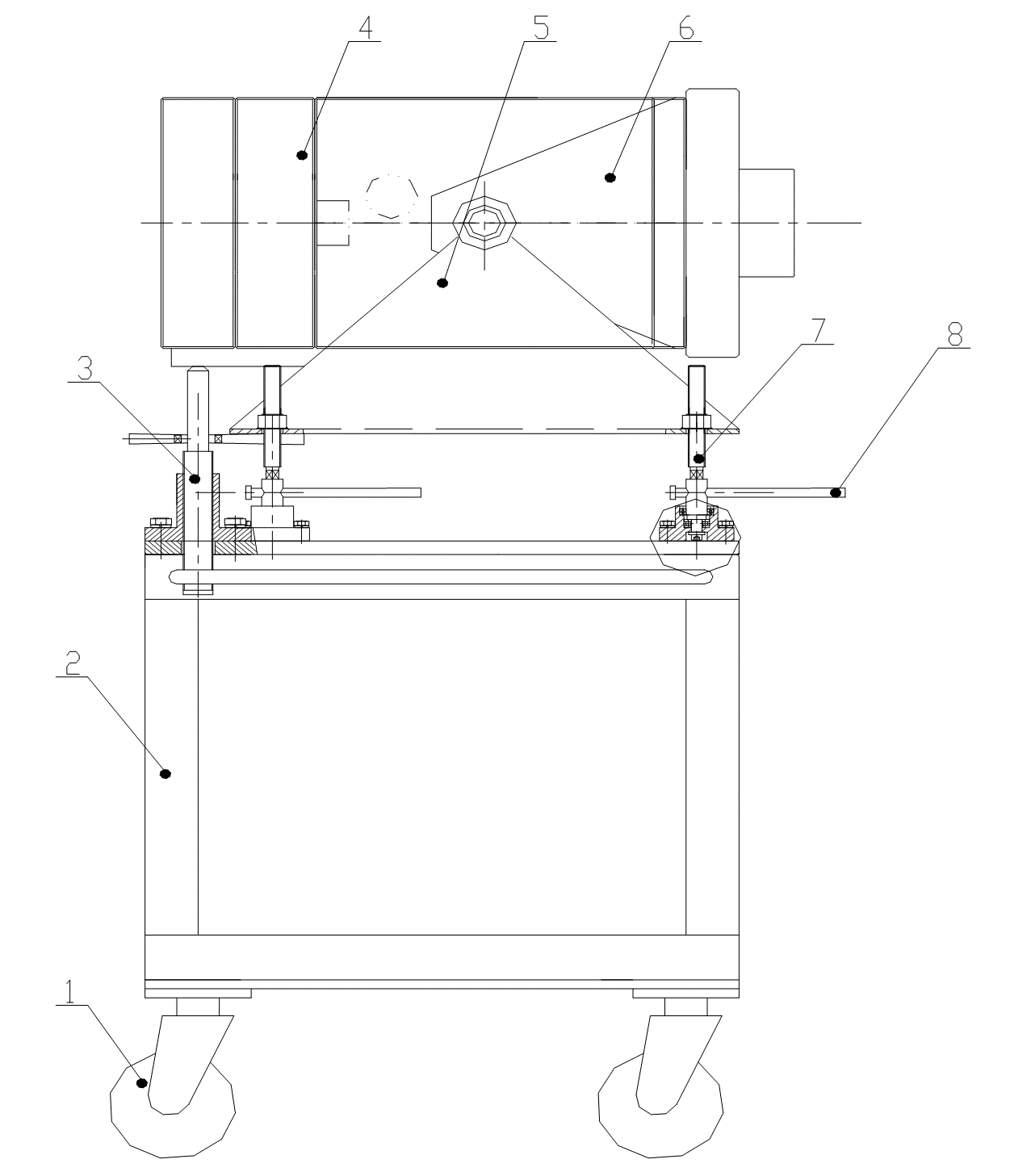

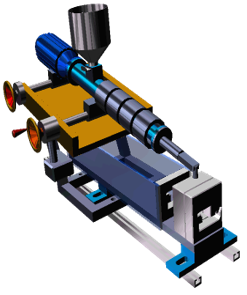

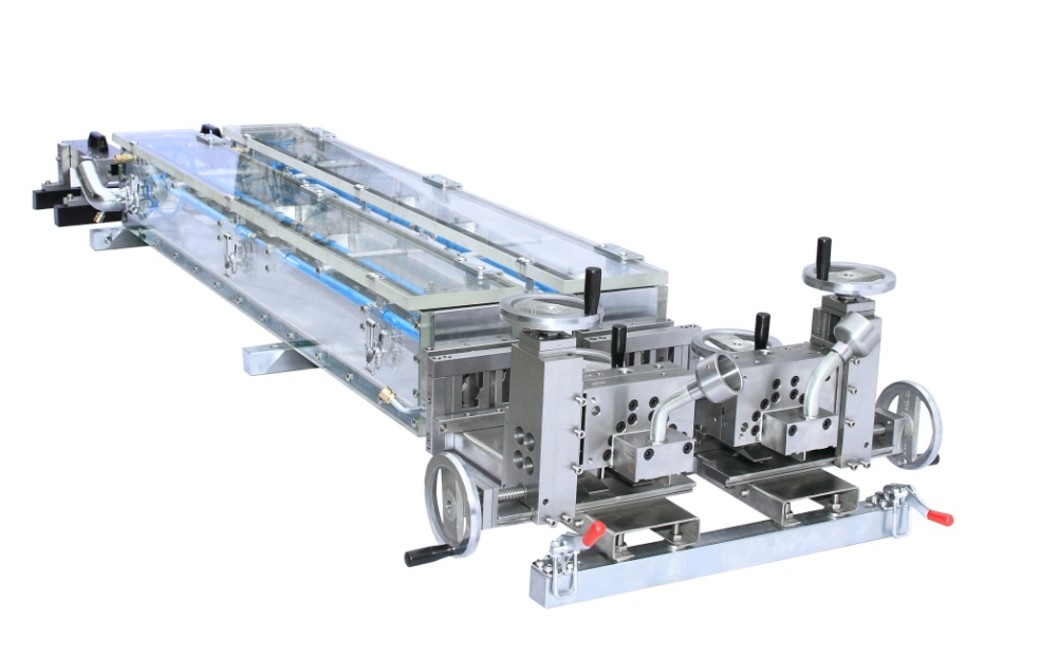

Downstream Equipment

Trinity can satisfy customers’ individual requirement and ensure customers’ extruded products with high quality.

Trinity offer customer the best performance/price ratio.

Trinity DS line is Equipped with all necessary features for modern extrusion, and optimized for extruding wide range of profiles.

Downstream Equipment

Trinity Special DS Line

Downstream Equipment

Trinity ECO Mode

– Calibration table are available from 3 ~ 5 meters long

– Automatic haul-off and cutting unit.

– Equipped with all necessary features for modern extrusion.

– Optimized for extruding wide range of profiles.

– Profile line speed can up to 10 m/min.

-Offer customer the best performance/price ratio.

Downstream Equipment

Trinity Energy Save DS Line

By Frequency conversion technology, Trinity now can make energy-saving downstream line, which can save 35%~45% power cost for customer.

New Products, New Technology

Extrusion Technique for Foam Profile

New Products, New Technology

WPC Extrusion Technique

New Products, New Technology

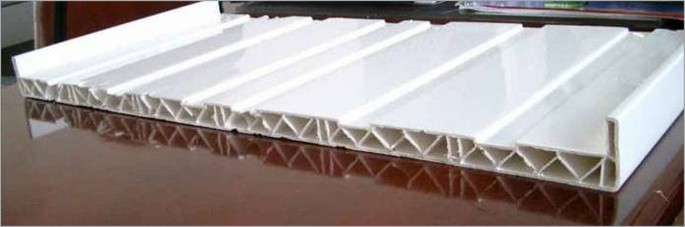

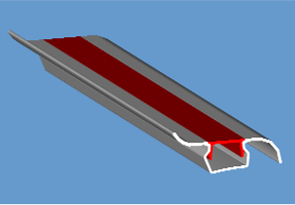

Extrusion Tooling for Panel & Sheet

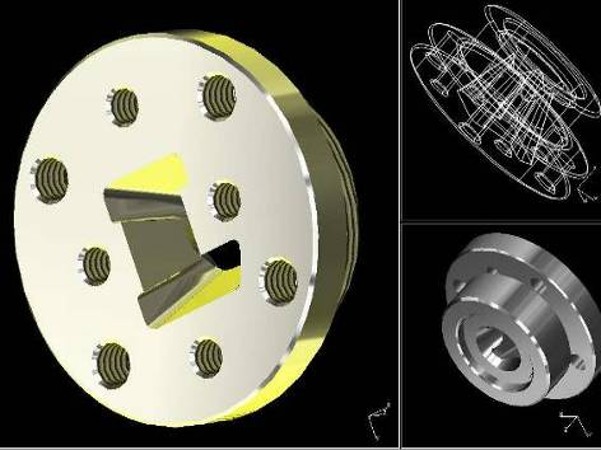

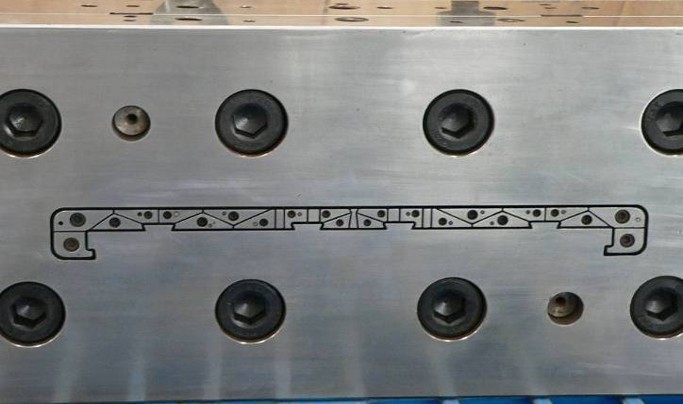

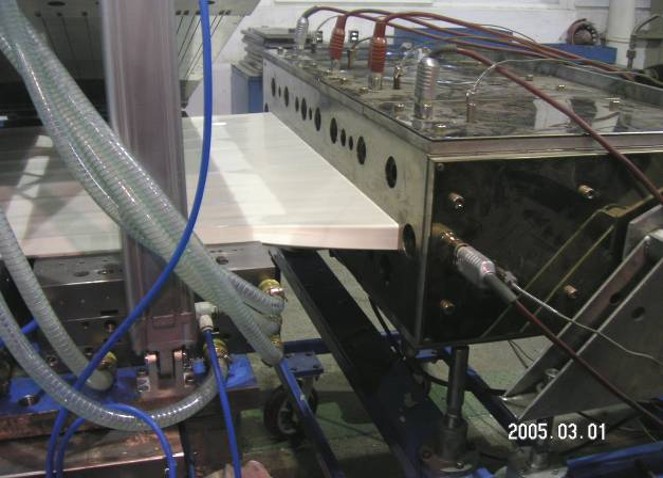

Die-head of sheet tooling

Tooling for sheet extrusion

Extrusion Engineering

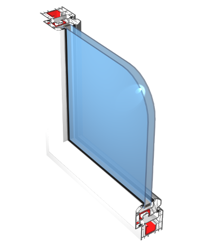

Window and Door Engineering

Leading & Experienced at PVC window & door marketing for more then 25 years, specialised at new Window & Door system designing for both European style and American style.

Extrusion Engineering

Window and Door Engineering

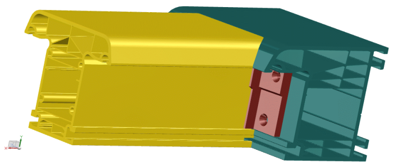

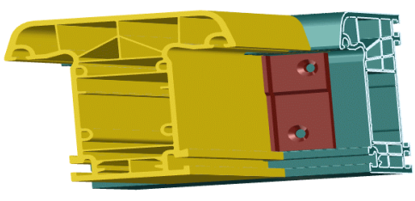

To have a direct view on final products after assembly, Trinity now is coming to use 3D software to prepare drawing.

Quality Control and Service

Quality Control System

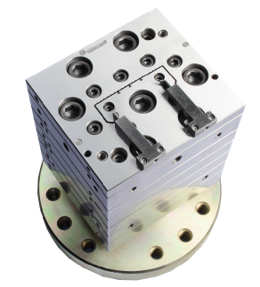

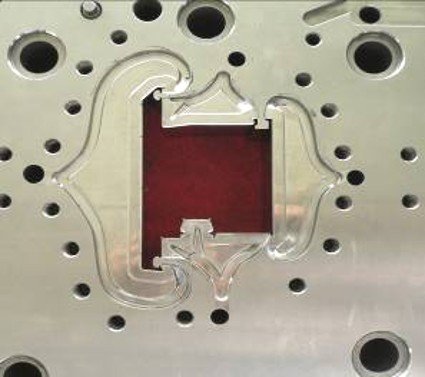

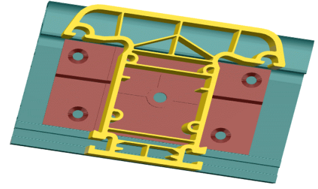

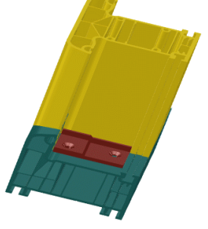

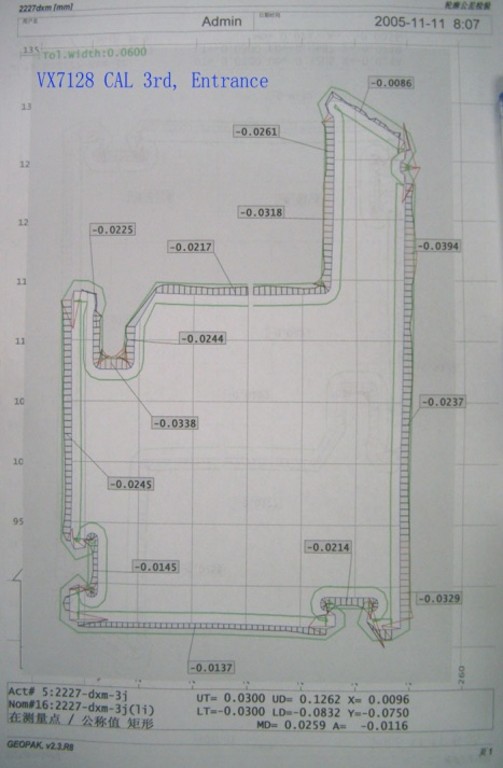

The Most Advanced Projector Inspection Equipment

Inspection equipment Mitutoyo is generally used to check tooling plate, especially for checking the flow chamber’s dimension after assembly, which will find precisely and inspector any different between actual dimension and designed data.

Quality Control and Service

Quality Control System

3D Inspector for Checking Profile’s Dimension

Inspection equipment with high precision are used to check all data of profile pre-tested to judge whether the products can satisfy customers’ requirements. The equipment we’re using now Includes Mitotoyo Janpan & Innox from Germany.

Cooperation/Clients

Trinity has cooperated with wide range of customer base.

Quality Control and Service

Pre-testing Inspection

Experienced technicians and designers, together with advanced extrusion lines including Weber, Cincinnati, Kraussmaffei, Theysohn etc., make Trinity Tooling of “0” blemish before delivery, which will save not only die-tuning time at site, but also cost for our customers.

More than 50 tuning technicians with advanced technology and rich experience can complete fine tuning and tooling modification at customer side.